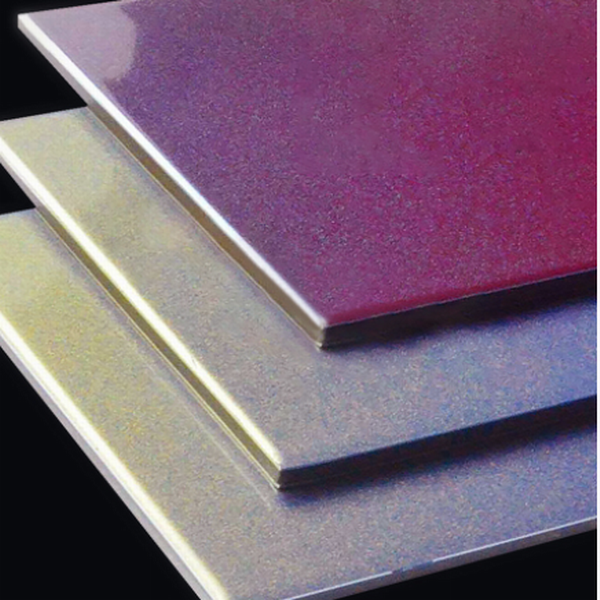

Top Quality Aluminium Composite Material - Aluminum-plastic Composite Panel – Jixiang Detail:

Product General

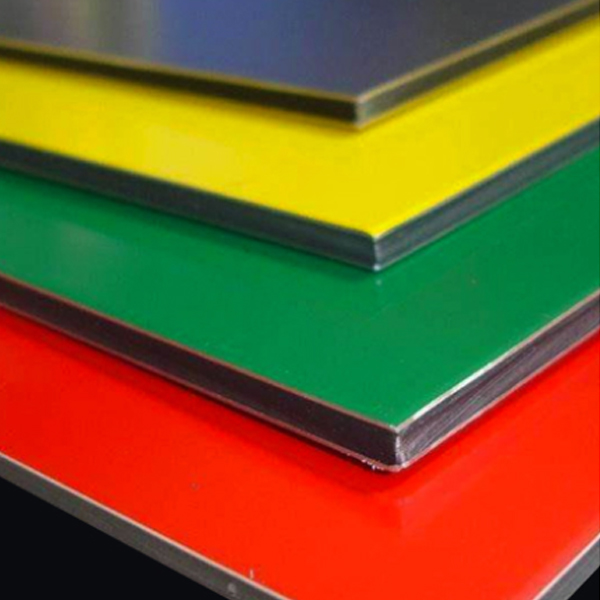

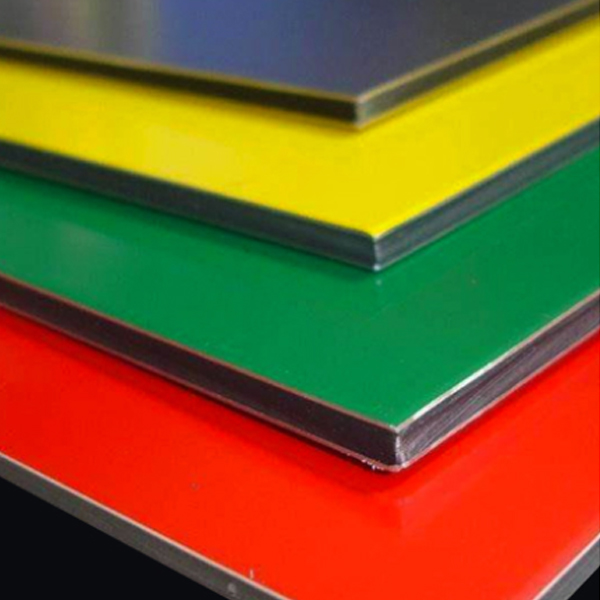

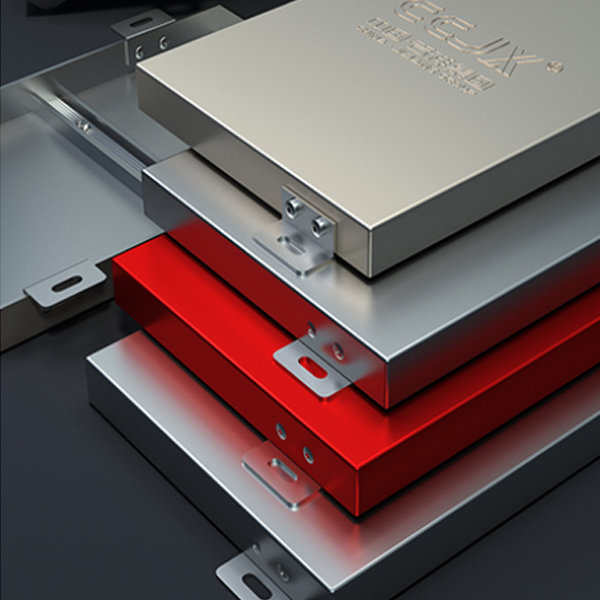

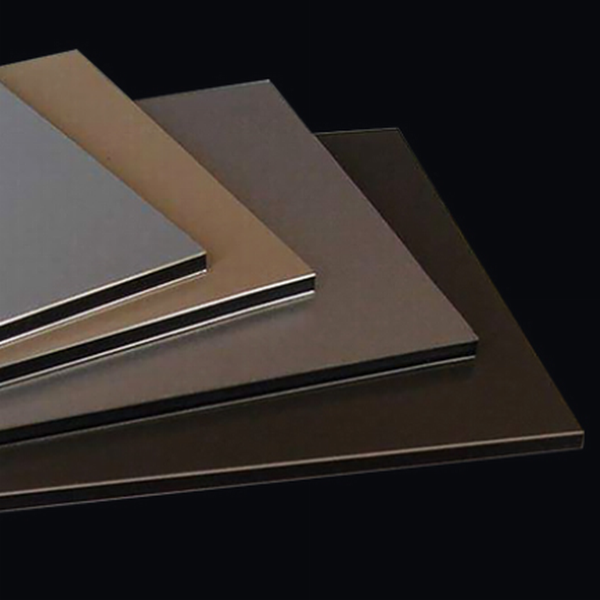

Aluminum Composite Panel is short as ACP.Its suface is made of aluminum sheet which surface is processed and baking coated by paint.It’s new type of material by compositing aluminum sheet with polyethylene core after a series technical processes.Because ACP is composited by two different material(metal and non-metal),it keeps the original material’s(metal aluminum and non-metal polyethylene) main characteristics and overcome the disadvantages of original material,so it obtains many excellent material performance,such as luxury and beautiful,colorful decoration;uv-proof,rust-proof,impact-proof,fire-proof,moisture-proof,sound-proof,heat-proof,

erthquake-proof;light and easy-processing,easy-shipping and easy-instailing.These performances make ACP a great future of usage.

lassification,specification

Classification:Normal AC and fire-proof ACP according to fire-proof performance

Specification: The regular specification for curtain wall ACP

is as following:

Length: 2000mm,2440mm,3000mm,3200mm,etc

Width: 1220mm,1250mm,1500mm,etc

Minimum thickness: 4mm

The length and width of curtain wall ACP can be decided by seller and buyer.

Size Tollerance Allowed

Thickness:Use 0.01mm degree measure device to test the panel thickness at points at least 20mm from panel edge.The test points at least include four corners and midpoints of four sides.The test result is the ultimate value difference between ail testing value and standard value.

Length (width):Use 1mm degree steel tape ruller to test two sides of length and two sides of width.The test result is the ultimate value difference between all testing value and standard value.use 1mm degree steel tape ruller to test diagonal lines of the same panel.The test result is the ultimate value difference between testing value.

Edge eveness: Put panel herizontally on a herizontal platform and put one side of 100omm long steel ruller along the panel edge,then test the maximum distance between steel ruller and panel edge by feeler.

Flatness: Put the panel herizontally on a herizontal platform with curling side up and put one side of 1000mm long steel ruller on the panel,then test the maximum distance between steel ruller and panel by o.5mm degree ruller.The test result is the maximum value difference among all testing values.

Alumium thickness:Take aluminum skin from ACP as test sample.Use minimum 0.001mm degree measure device to test almuminum thickness(without coating thickess,etc).The test points should be ample,but four corners and central point of each sample should be tested.The test result is the

minimum value and averave value among all testing values.

Coating thickness: It means the total thickness of coating.According to GB/T4957,the test points should be ample,but four corners and central point of each sample should be tested.The test result is the minimum value and averave value among all testing values.

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Top Quality Aluminium Composite Material - Aluminum-plastic Composite Panel – Jixiang, The product will supply to all over the world, such as: Durban, Bulgaria, Miami, Nowadays our merchandise sell all over the domestic and abroad thanks for the regular and new customers support. We supply high quality product and competitive price, welcome the regular and new customers cooperate with us!

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!

-

factory low price Aluminium Composite Facade -...

-

Manufactur standard Forming Aluminum Sheet Meta...

-

2020 New Style Aluminum Frieze Board - Antibac...

-

Super Lowest Price Expandable Aluminum Sheet -...

-

Wholesale Price Pvdf Coating Aluminum Core Comp...

-

Best quality Brushed Aluminum Composite Panel -...