Non-combustible metal composite board

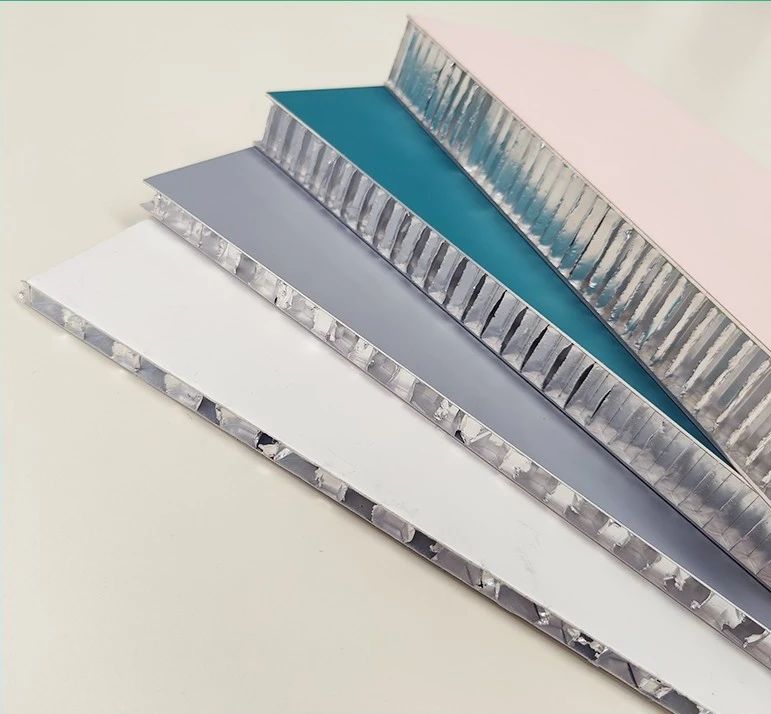

The process uses chemically treated coated aluminum plate as the surface material

Through hot pressing process

On special aluminum composite board production equipment

The metal panel, base plate, and fireproof core material

Combined into an integrated board

So it has excellent fireproof performance and flatness

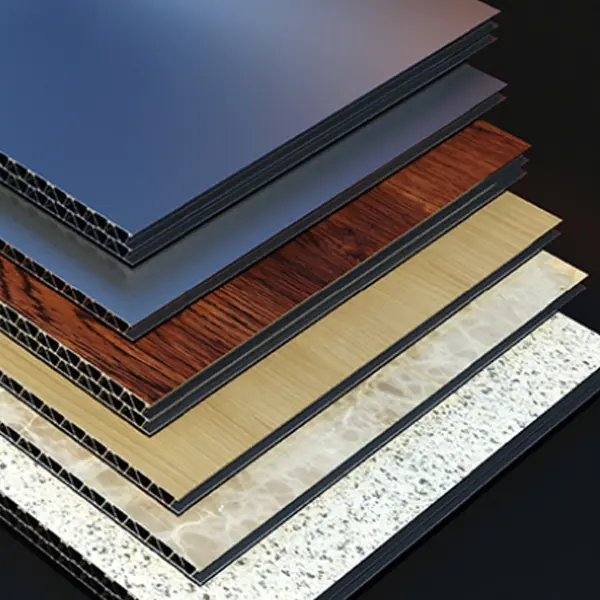

And the surface can be treated with a variety of textures

Such as stone grain, wood grain, brushed, anodized, etc.

The unique properties of aluminum composite board itself

Determine that it has a wide range of uses

Building exterior walls, old building renovation, interior walls and ceilings

Ship, RV, B&B, hotel, villa can be used

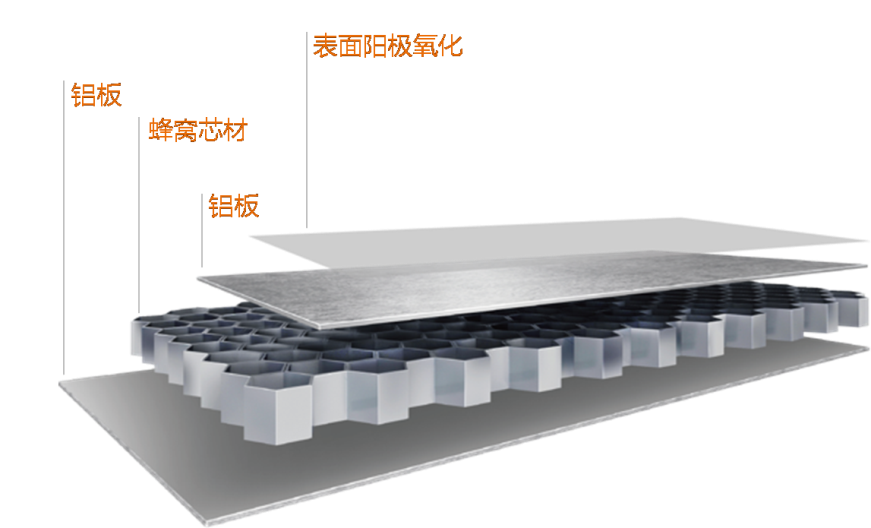

Next, let's focus on the anodized non-combustible metal composite board. Anodized aluminum composite board can be divided into anodized honeycomb composite board and anodized non-combustible core composite board according to the different substrates.

It is composed of a panel (anodized aluminum panel), a panel back (aluminum panel) and an intermediate layer (aluminum honeycomb core material).

Material features:

1.B-grade fireproof, durable and weather-resistant, waterproof and moisture-proof, recyclable

2.The panel is light and flat, suitable for large panels

3.A variety of PP/PET film finishes, good appearance

4.Various specifications, suitable for indoor ceiling panels/wall panels/furniture panels, realizing the integrated design of doors, walls, ceilings and cabinets

5.Can be slotted and folded at the back

6.Disadvantages: Cannot punch holes, poor impact resistance

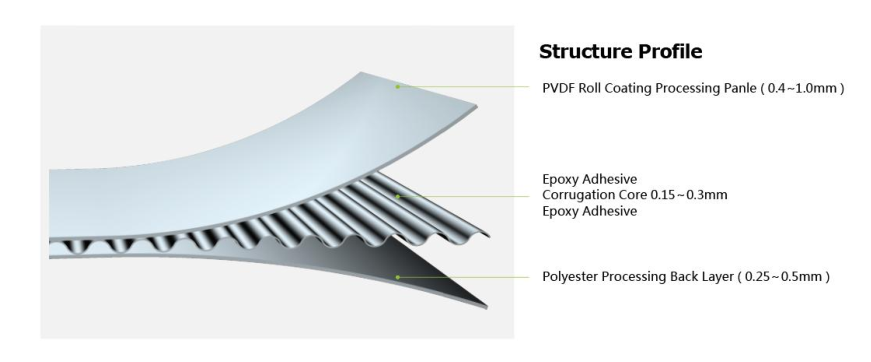

It is a "sandwich" structure, which uses hot pressing process to combine oxidized thick film aluminum plate, back aluminum plate and fireproof core material into one board.

The middle layer is composed of flame-retardant non-toxic inorganic mineral core material

Metal material composite technology

It can give full play to the advantages of each component material

Achieve the optimal configuration of each component material resource

Achieve performance requirements that cannot be met by a single metal

Material characteristics:

1.Metallic luster, high-grade texture

2.Continuous oxidation process to ensure decorative effect, no obvious color difference

3.Surface metal film is super weather-resistant, antibacterial, mildew-proof and easy to clean

4.Surface hardness reaches 9H (sapphire grade hardness), scratch-resistant and wear-resistant

5.Good weather resistance, no fading for 50 years, the same life as the building

6.Combustion performance reaches non-combustible A (A2s1, d0, t0) level

7.Can punch holes, slot and fold corners, special-shaped processing is not as good as single board

8.Suitable for large board width, super flat

9.High cost performance

Post time: Jun-13-2024