In the context of the rapid development of global industry and economy, it is increasingly difficult for a single component of metal materials to meet the harsh use environment. Therefore, researchers have developed a method of combining two or more metal materials together to make metal composite plates and then processing them into equipment, so that they can be used under extreme working conditions such as high temperature and heavy load, strong acid and strong alkali.

Metal composite plates have the performance of both substrates and composite plates, reducing the use of rare metals. At the same time, they have been widely used in new fields such as petrochemicals, marine ships, and power environmental protection.

Composed of two materials with completely different properties (metal and non-metal), it not only retains the main characteristics of the original constituent materials (metal aluminum, non-metal polyethylene plastic), but also overcomes the shortcomings of the original constituent materials, thereby obtaining many excellent material properties, such as luxury, colorful decoration, weather resistance, corrosion resistance, impact resistance, fire resistance, moisture resistance, sound insulation, heat insulation, earthquake resistance; light weight, easy processing and molding, easy handling and installation, etc.

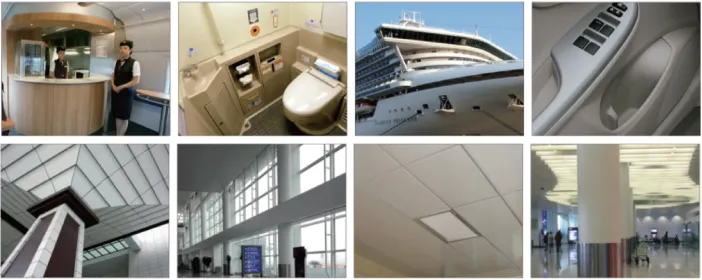

Therefore, it is widely used in various architectural decorations, such as ceilings, column wrapping, counters, furniture, telephone booths, elevators, storefronts, billboards, factory wall materials, etc. It has become the representative of metal curtain walls among the three major curtain walls (natural stone, glass curtain wall, metal curtain wall). In developed countries, aluminum-plastic panels are also used in the manufacture of buses and train carriages, sound insulation materials for airplanes and ships, and design of instrument boxes.

Aluminum corrugated core composite aluminum plate

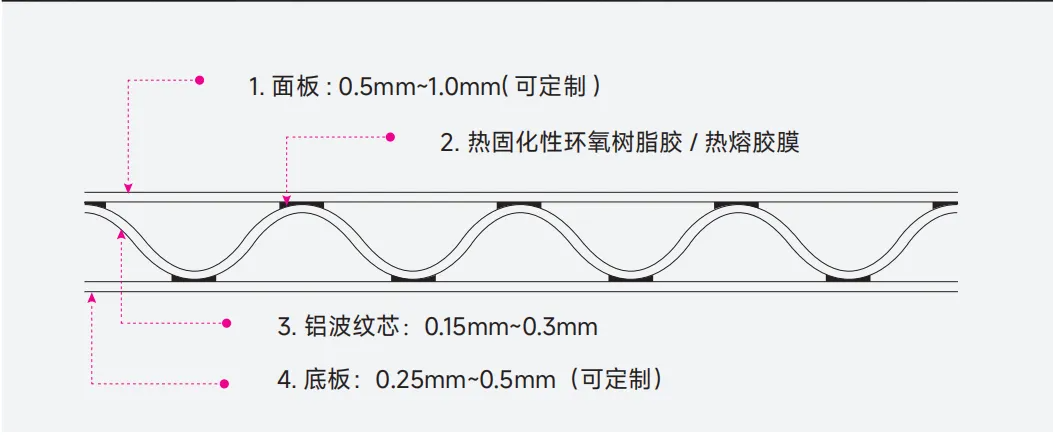

Aluminum corrugated core composite aluminum plate is also called aluminum corrugated composite plate. We use fluorocarbon roller coating to treat the panel, double-sided roller coating of the corrugated core with two-component epoxy resin glue, and the surface-treated back plate to form our aluminum corrugated core composite aluminum plate.

The fully automatic production line equipment of aluminum corrugated core composite aluminum plate developed by China Jixiang Group makes the aluminum corrugated core composite aluminum plate better than the national manufacturing standard and improves the performance indicators of the product.

It has economic efficiency, high flatness, a variety of optional colors, convenient construction methods, excellent processing performance, and excellent fire resistance.

2、Applicable scenarios of metal composite aluminum plate

Post time: Mar-26-2025