Green, environmentally friendly, antibacterial, fireproof

Keep peace of mind

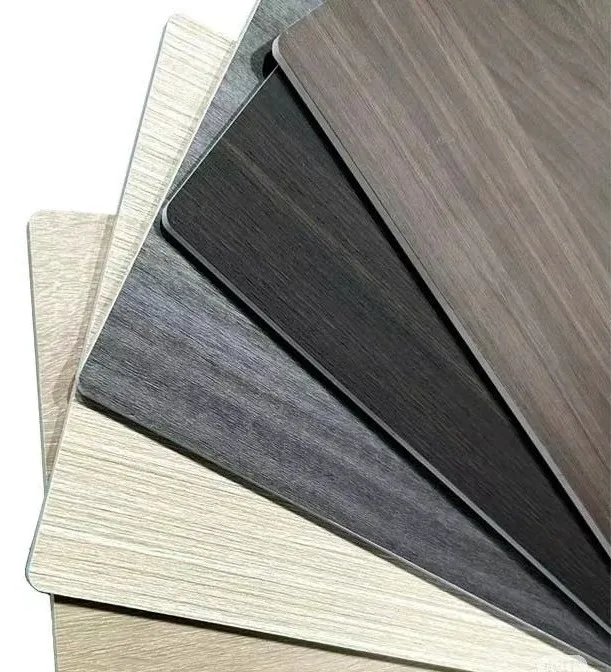

Metal composite board

Flame retardant metal composite board

Product structure and performance

Many building applications today require higher fire protection standards and certified materials. The emergence of flame-retardant metal composite panels is of great significance. It not only meets the basic requirements of fire safety, but also has the beauty of architectural decoration applications. Its processing and installation methods are as simple and convenient as ordinary metal composite panels.

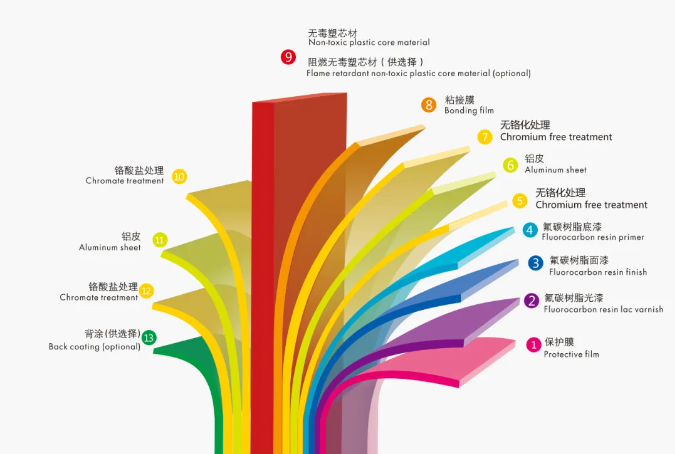

Metal composite panel product structure

Specifications can be customized according to customer requirements

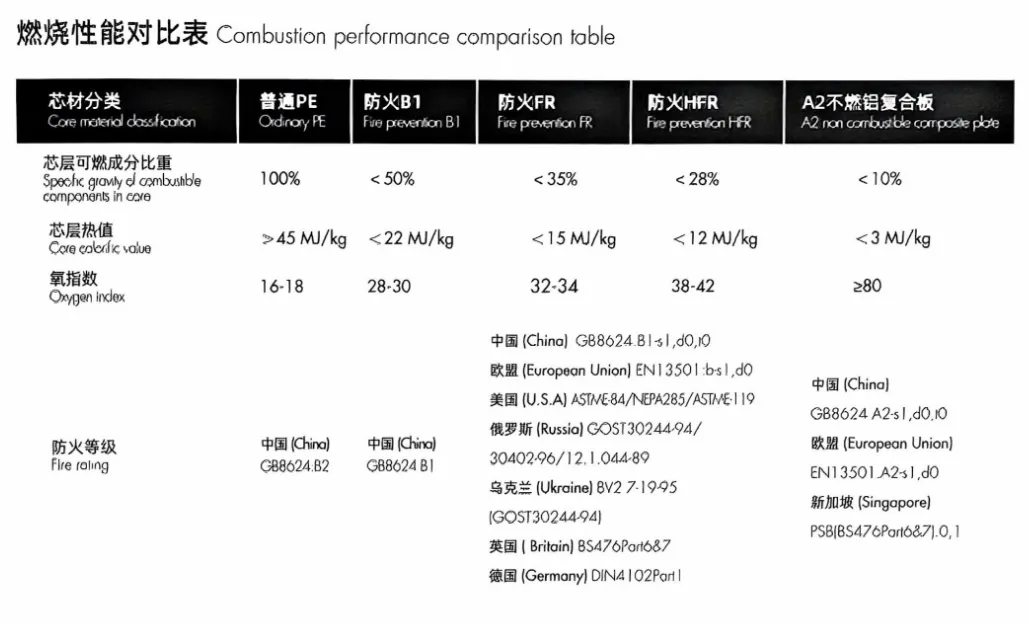

Comparison of Combustion Performance

The combustion performance of building materials is divided into four flame retardant grades: B1, FR, HFR, and A2.

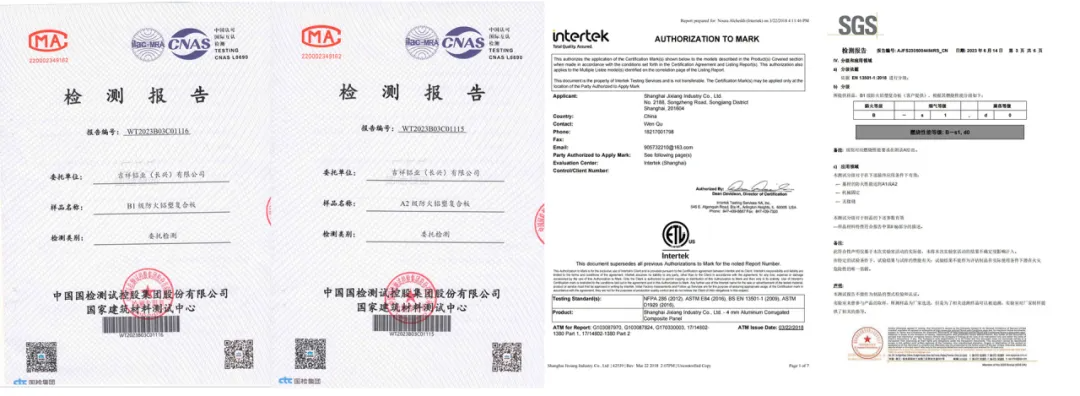

The flame retardant metal composite panels produced by CCJX® China Jixiang Group have been tested by authoritative organizations such as SGS, INTERTEK, and the National Inspection and Quarantine Agency, reaching B1 and A2 grades respectively.

Product Advantages

1: Low material quality:

Metal composite aluminum plate is made of aluminum foil and plastic core material with relatively low density. Therefore, it has a smaller mass than aluminum plate (or other metal) with the same rigidity or thickness, and even smaller mass than glass and stone. Therefore, it can reduce the damage caused by earthquake disasters, and is easy to carry, while saving transportation costs.

2: High surface flatness and super strong peeling degree

Metal composite aluminum plate is produced by continuous hot composite production process, and its surface flatness is high. Metal composite aluminum plate adopts new technology to improve the most critical technical indicator of metal composite aluminum plate-peeling strength to an excellent state, so that the flatness and weather resistance of metal composite aluminum plate are improved accordingly.

3. Impact resistance

Strong impact resistance, high toughness, bending does not damage the topcoat, and there will be no damage caused by wind and sand in areas with strong wind and sand.

4. Super weather resistance

It has unique advantages in weather resistance whether in hot sunshine or severe cold. The beautiful appearance will not be damaged in the wind and snow, and it will not fade for 20 years.

5. Excellent fireproof performance

The metal composite aluminum plate has a flame-retardant PE plastic core in the middle and an extremely difficult-to-burn aluminum layer on both sides. Therefore, it is a safe fireproof material that meets the fire resistance requirements of building regulations

7. Uniform coating, diverse colors, and strong decorative properties

After chemical treatment and the application of Henkel film technology, the adhesion between the paint and the aluminum-plastic plate is uniform and consistent, and the colors are diverse, giving you more room for choice and showing your personalization.

8. Easy maintenance

The metal composite aluminum plate has been significantly improved in terms of pollution resistance. Urban pollution in my country is relatively serious, and maintenance and cleaning are required after a few years of use. Due to its good self-cleaning property, only neutral detergent and clean water are needed, and the plate will be permanently as new after cleaning.

9. Easy to process

The metal composite aluminum plate is a good material that is easy to process and form. It is also an excellent product that saves time in pursuit of efficiency, which can shorten the construction period and reduce costs. Its superior construction performance only requires simple tools to complete cutting, trimming, planing, bending into arcs, right angles and various shapes. It can also be cold-bent, cold-folded, cold-rolled, riveted, screwed or glued. It can cooperate with designers to make various changes. It is easy to install and quickly reduces construction costs.

9. Green environmental protection and good cost-effectiveness.

The production of metal composite aluminum plate adopts pre-coating continuous coating and continuous hot composite process of metal/core material. Compared with general metal single plate, it has high production efficiency and low raw material cost. It is a material with good cost characteristics. The aluminum and plastic core materials in the discarded metal composite aluminum plate can be 100% recycled and used, with low environmental load.

Applications

Metal composite aluminum plate applicable scenarios

Decorative curtain walls, home panels, advertisements and display boards, hospitals, rail transit, etc.

Post time: Aug-16-2024