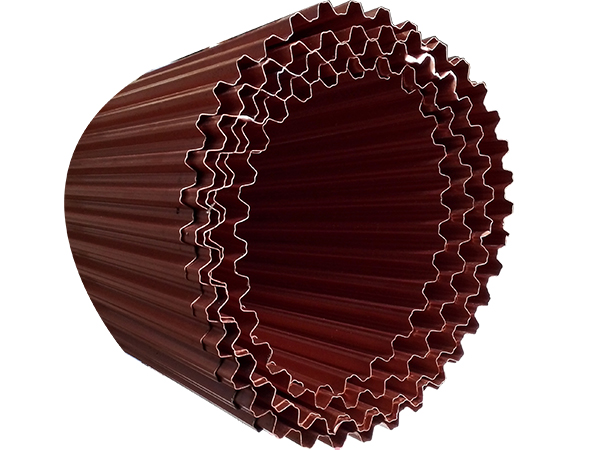

Aluminum corrugated core composite board must have the ability of saving resources and reducing cost. Generally, two coating and one drying (two coating and two drying) or quality problems, such as serious loose edge, loose center in the middle, missing coating, large serrated edge, serious ellipse and irregularity, can not be used in the production of composite board. There are many advantages in the use of aluminum corrugated core composite board. Take their corrosion resistance as an example, and there will be no corrosion during use. In this way, the cost of use can be reduced to a certain extent. There are also many boards made of solid wood.

Aluminum corrugated core composite board, wood composite board, composite board is generally divided into: metal composite board. Color steel composite board, rock wool composite board and so on! It refers to covering a layer of metal plate with another metal plate to achieve the effect of saving resources and reducing cost without reducing the use effect (corrosion resistance, mechanical strength, etc.). There are usually explosive bonding, explosive rolling, rolling and so on. Composite data can be divided into composite plate, composite tube and composite rod. It is mainly used in anticorrosion, pressure vessel manufacturing, power construction, petrochemical, medicine, light industry, automobile and other industries.

Post time: Nov-05-2020